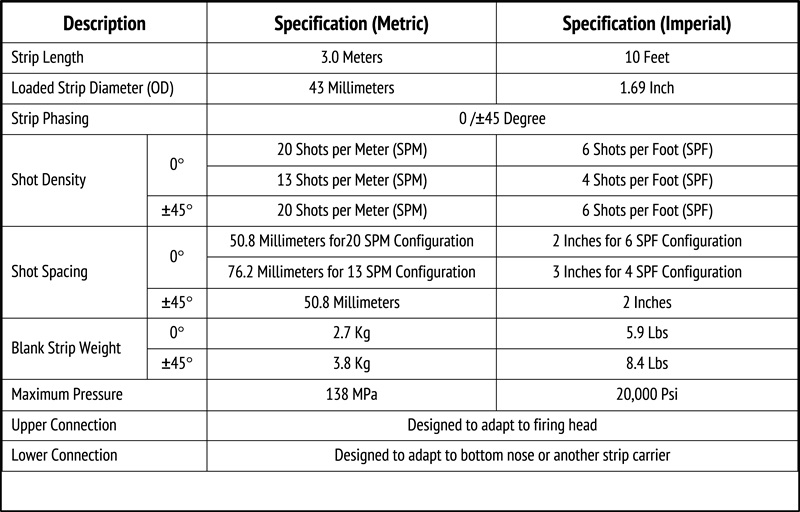

Strip Carrier Perforating is a high performance semi-expendable carrier system for through-tubing applications. The steel-case encapsulated charge mounted on a retrievable steel carrier strip provides a more powerful explosive load than equivalent diameter retrievable hollow scalloped carriers. The carrier strips are recovered after firing with the charge front caps in place, leaving small amounts of debris from the charge case in the well.

| 1 11/16” Charges | Part Number | 2 1/8” Charges | Part Number |

|---|---|---|---|

| 1 11/16” STR 8.4G RDX DP | 91688110 | 2 1/8” STR 13.9G RDX DP | 92125110 |

| 1 11/16” STR 8.4G RDX SDP | 91688120 | 2 1/8” STR 13.9G RDX SDP | 92125120 |

| 1 11/16” STR 8.4G HMX DP | 91688114 | 2 1/8” STR 13.9G HMX DP | 921252114 |

| 1 11/16” STR 8.4G HMX SDP | 91688124 | 2 1/8” STR 13.9G HMX SDP | 921252124 |

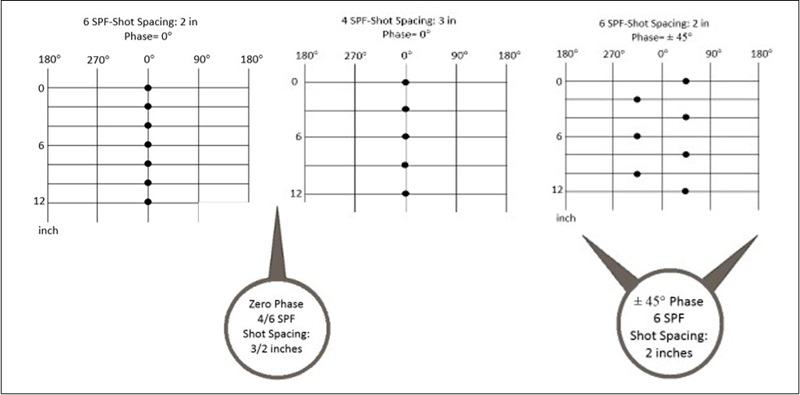

Below diagram shows the shot pattern made by a 1 11/16” strip carrier. Each mark on the grid represents an individual shot.

Below diagram shows the shot pattern made by a 6SPF, 60 Degree phased 2 7/8” carrier. Each mark on the grid represents an individual shot, separated from the next by 60 degrees radially and 2” vertically.

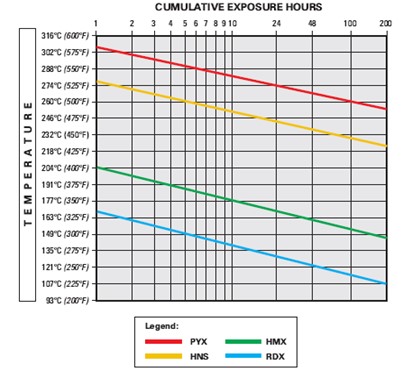

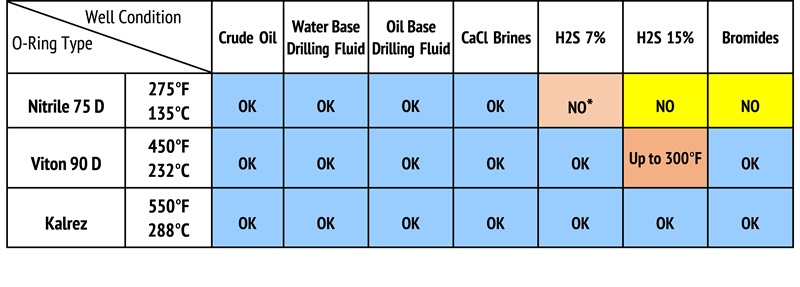

Downhole temperature will determine the type of shaped charge and detonating cord to be used. Refer to below Chart-1 for temperature versus time curve. These two factors determine the appropriate O-ring seal material to be used in the assembly. Based on Chart 2 below, Viton O-rings are recommended for Tubing Conveyed Perforating (TCP) systems and Nitrile O-rings are recommended for wireline applications.